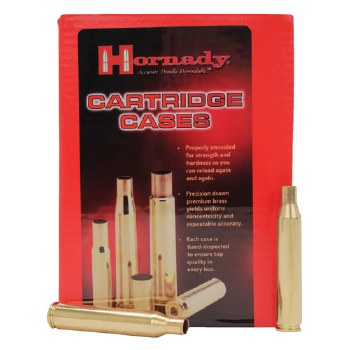

22-250 Small Primer Brass Overview

Remington cartridge(22-250 Small Primer Brass ) cases carefully drawn from specially-alloyed brass to provide consistently exact internal volume. Also resistance to case stretching and brittleness. Primer pocket tolerances held to .001″, and also closely monitored case neck annealing ensures easier re-sizing and also longer reloading life. New, unprimed brass. This not loaded ammunition. Bulk brass should be full-length sized, trimmed and chamfered before loading.

Brass Preparation: With bulk rifle brass you may sometimes notice a few case mouths are “out of round” or slightly dented below the shoulder. These imperfections occur in the final tumbling wash operation after the case mouth has annealed. Brass manufacturers are aware of the case cosmetics and have worked to mitigate it, but due to equipment design, denting may still occur. Minor dents normally removed in the first firing and will not affect case life or performance. On non-plated brass, you may also notice all the anneal stain might not polished off, which may give the case neck a pinkish color. With some smaller caliber cases you may notice the case mouths to be slightly belled.

With all new rifle brass, you should first straighten out the case and case mouth, then chamfer and debur the case mouth inside and out. To straighten the case mouth, run the case part way into the sizer die and let the expander ball straighten the brass. To prevent the case neck from stretching, be sure to lubricate the case neck inside the case mouth.

If you using Nickel plated brass, special care must lubricate the cases prior to sizing them. Nickel plating is harder than brass and the cases require more effort in sizing. In the event a case becomes stuck, purchase a stuck case remover; don’t use pliers, screwdrivers or other common household tools which could damage your sizing die.

Made In United States of America

Reviews

There are no reviews yet.